Diode laser technology has revolutionized the field of hair removal, providing a safe and effective…

Revolutionizing Manufacturing with Fiber Laser Technology

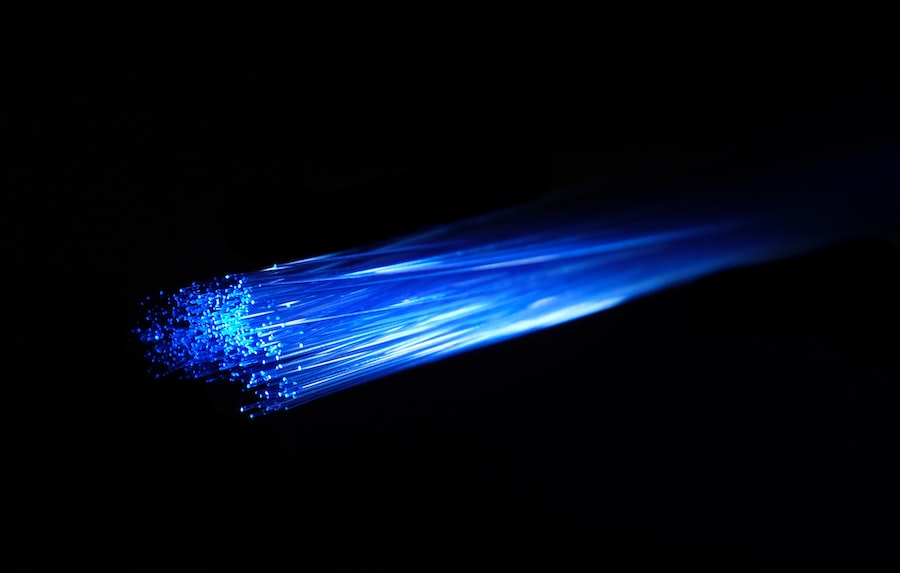

Fiber laser technology is a type of laser technology that utilizes optical fibers as the gain medium for amplifying light. It is a relatively new technology that has gained significant popularity in various industries, especially in manufacturing. Fiber lasers offer several advantages over traditional laser technologies, such as higher cutting speed, better beam quality, and higher energy efficiency.

The history of fiber laser technology can be traced back to the 1960s when researchers began experimenting with using optical fibers as a medium for amplifying light. However, it was not until the 1990s that fiber lasers started to gain commercial viability. Since then, there have been significant advancements in fiber laser technology, leading to its widespread adoption in various applications.

Advantages of Fiber Laser Technology in Manufacturing

One of the key advantages of fiber laser technology in manufacturing is its higher cutting speed. Fiber lasers can cut through materials at a much faster rate compared to traditional laser technologies. This increased cutting speed translates into higher productivity and shorter production times. Manufacturers can produce more products in less time, leading to increased efficiency and profitability.

Another advantage of fiber laser technology is its lower maintenance costs. Traditional laser technologies require regular maintenance and replacement of components such as flash lamps and mirrors. In contrast, fiber lasers have a longer lifespan and require minimal maintenance. This not only reduces downtime but also lowers the overall operating costs for manufacturers.

Furthermore, fiber lasers offer better beam quality compared to traditional lasers. The high beam quality of fiber lasers results in cleaner cuts with smoother edges and minimal distortion. This is particularly important for industries that require high precision and accuracy, such as aerospace and medical device manufacturing.

Lastly, fiber lasers are more energy-efficient compared to traditional lasers. They convert a higher percentage of electrical energy into laser light, resulting in less wasted energy in the form of heat. This energy efficiency not only reduces operating costs but also contributes to a more sustainable manufacturing process.

Cost Savings in Manufacturing with Fiber Laser Technology

The adoption of fiber laser technology in manufacturing can lead to significant cost savings for companies. One area where cost savings can be achieved is through reduced material waste. Fiber lasers offer precise and accurate cutting, resulting in minimal material waste. This is particularly beneficial for industries that work with expensive materials, such as aerospace and automotive manufacturing.

In addition to reduced material waste, fiber lasers also contribute to lower energy consumption. As mentioned earlier, fiber lasers are more energy-efficient compared to traditional lasers. This means that manufacturers can save on electricity costs and reduce their carbon footprint by using fiber laser technology.

Furthermore, the lower maintenance requirements of fiber lasers result in reduced labor costs. Traditional lasers often require regular maintenance and replacement of components, which can be time-consuming and costly. With fiber lasers, manufacturers can minimize the need for maintenance and allocate their resources more efficiently.

Lastly, the overall lower operating costs of fiber laser technology contribute to cost savings for manufacturers. The combination of reduced material waste, lower energy consumption, and lower maintenance costs results in a more cost-effective manufacturing process.

Improved Precision and Accuracy in Manufacturing

Precision and accuracy are crucial factors in manufacturing, especially in industries that require intricate and complex parts. Fiber laser technology offers several advantages in terms of precision and accuracy.

One of the key advantages is higher cutting accuracy. Fiber lasers can achieve extremely fine cuts with high precision, allowing manufacturers to produce parts with tight tolerances. This is particularly important in industries such as aerospace and medical device manufacturing, where precision is critical.

Furthermore, fiber lasers offer better edge quality compared to traditional lasers. The high beam quality of fiber lasers results in cleaner cuts with minimal burrs and rough edges. This not only improves the aesthetics of the finished product but also reduces the need for additional post-processing steps.

Moreover, fiber lasers can help reduce distortion during the cutting process. Traditional laser technologies often generate heat, which can cause distortion in the material being cut. Fiber lasers, on the other hand, produce less heat, resulting in reduced distortion and better overall part quality.

Lastly, fiber lasers offer improved repeatability in manufacturing. The high precision and accuracy of fiber lasers ensure consistent results, even when producing large quantities of parts. This is particularly beneficial for industries that require high-volume production.

Increased Production Efficiency with Fiber Laser Technology

Fiber laser technology can significantly improve production efficiency in manufacturing. One of the key factors contributing to increased efficiency is higher throughput. Fiber lasers can cut through materials at a much faster rate compared to traditional lasers, resulting in higher production speeds. Manufacturers can produce more parts in less time, leading to increased productivity and profitability.

Another factor contributing to increased efficiency is reduced downtime. Traditional laser technologies often require regular maintenance and replacement of components, which can result in significant downtime. With fiber lasers, manufacturers can minimize the need for maintenance and keep their production lines running smoothly.

Furthermore, fiber laser technology offers improved process control. The high precision and accuracy of fiber lasers allow manufacturers to have better control over the cutting process. This means that they can achieve consistent results and minimize errors or defects in their products.

Additionally, fiber lasers offer faster setup times compared to traditional lasers. The setup process for fiber lasers is relatively quick and straightforward, allowing manufacturers to start production faster. This reduces the time wasted on setup and increases overall production efficiency.

Diverse Applications of Fiber Laser Technology in Manufacturing

Fiber laser technology has a wide range of applications in manufacturing. One of the most common applications is cutting. Fiber lasers are used for cutting various materials such as metals, plastics, and composites. They offer precise and accurate cuts with minimal material waste, making them ideal for industries that require high-quality cuts.

Another application of fiber laser technology is welding. Fiber lasers can be used for both spot welding and seam welding. They offer high welding speeds and excellent weld quality, making them suitable for industries such as automotive and electronics manufacturing.

Fiber lasers are also used for marking and engraving. They can create permanent marks on various materials, including metals, plastics, and ceramics. This is particularly useful for industries that require product labeling or branding.

Furthermore, fiber laser technology is used in additive manufacturing, also known as 3D printing. Fiber lasers can be used to selectively melt or sinter materials to create complex 3D objects. This is a rapidly growing field with applications in industries such as aerospace, healthcare, and automotive.

Fiber Laser Technology and Sustainability in Manufacturing

Fiber laser technology offers several sustainability benefits in manufacturing. One of the key benefits is reduced environmental impact. Traditional laser technologies often use hazardous materials such as mercury in their components. Fiber lasers, on the other hand, do not require such materials, making them more environmentally friendly.

Moreover, fiber lasers have a lower carbon footprint compared to traditional lasers. As mentioned earlier, fiber lasers are more energy-efficient, resulting in less energy consumption and lower greenhouse gas emissions. This contributes to a more sustainable manufacturing process and helps companies meet their sustainability goals.

Additionally, fiber lasers contribute to reduced material waste. The high precision and accuracy of fiber lasers result in minimal material waste during the cutting process. This not only reduces costs but also minimizes the amount of waste sent to landfills.

Furthermore, the lower maintenance requirements of fiber lasers contribute to sustainability. Traditional lasers often require regular maintenance and replacement of components, which can result in the generation of waste. With fiber lasers, manufacturers can minimize the need for maintenance and reduce the amount of waste generated.

Fiber Laser Technology and Industry 4.0

Fiber laser technology plays a crucial role in the implementation of Industry 4.0 principles in manufacturing. Industry 4.0 refers to the integration of digital technologies into the manufacturing process to create a more connected and automated production environment.

One of the key aspects of Industry 4.0 is the integration of digital technologies with physical manufacturing processes. Fiber laser technology can be easily integrated with other digital technologies such as robotics, artificial intelligence, and data analytics. This allows for seamless communication and coordination between different components of the manufacturing process.

Moreover, fiber laser technology enables improved data collection and analysis. Fiber lasers can be equipped with sensors and monitoring systems that collect data on various parameters such as cutting speed, power, and beam quality. This data can then be analyzed to identify patterns, optimize processes, and improve overall production efficiency.

Furthermore, fiber laser technology enables increased automation in manufacturing. The high precision and accuracy of fiber lasers make them ideal for automated production lines. Manufacturers can integrate fiber lasers with robotic systems to achieve higher levels of automation and reduce the need for manual intervention.

Additionally, fiber laser technology contributes to improved supply chain management. The high cutting speed and accuracy of fiber lasers allow for faster production times and shorter lead times. This enables manufacturers to respond quickly to customer demands and reduce inventory levels.

Future of Manufacturing with Fiber Laser Technology

The future of manufacturing with fiber laser technology looks promising. There are several advancements being made in fiber laser technology that will further enhance its capabilities and applications.

One area of advancement is in power scaling. Researchers are working on developing fiber lasers with higher power outputs, allowing for even faster cutting speeds and increased productivity. This will open up new possibilities for industries that require high-volume production.

Another area of advancement is in beam quality. Researchers are exploring ways to improve the beam quality of fiber lasers, resulting in even cleaner cuts with smoother edges. This will be particularly beneficial for industries that require high precision and accuracy.

Furthermore, there is an increasing adoption of fiber laser technology in various industries. As more manufacturers recognize the benefits of fiber lasers, the demand for this technology is expected to grow. This will lead to increased competition and further advancements in fiber laser technology.

Moreover, fiber laser technology is being integrated with other technologies such as robotics, artificial intelligence, and additive manufacturing. This integration will enable manufacturers to create more advanced and efficient production processes.

The Impact of Fiber Laser Technology on Manufacturing

In conclusion, fiber laser technology has had a significant impact on the manufacturing industry. Its advantages in terms of higher cutting speed, lower maintenance costs, better beam quality, and higher energy efficiency have made it a preferred choice for many manufacturers.

The cost savings achieved through reduced material waste, lower energy consumption, reduced labor costs, and lower maintenance costs contribute to the overall profitability of manufacturers.

The improved precision and accuracy offered by fiber laser technology result in higher quality products with minimal defects. This is particularly important for industries that require high precision and accuracy.

The increased production efficiency achieved through higher throughput, reduced downtime, improved process control, and faster setup times allows manufacturers to meet customer demands more effectively and increase their competitiveness.

The diverse applications of fiber laser technology in cutting, welding, marking, engraving, and additive manufacturing make it a versatile tool for various industries.

Furthermore, fiber laser technology contributes to sustainability in manufacturing through reduced environmental impact, lower carbon footprint, reduced material waste, and lower energy consumption.

The integration of fiber laser technology with digital technologies enables the implementation of Industry 4.0 principles in manufacturing. This leads to increased automation, improved data collection and analysis, and enhanced supply chain management.

The future of manufacturing with fiber laser technology looks promising with advancements in power scaling, beam quality, and integration with other technologies.

Overall, fiber laser technology has revolutionized the manufacturing industry and will continue to play a crucial role in shaping the future of manufacturing.

FAQs

What is a fiber laser?

A fiber laser is a type of laser that uses optical fibers as the active gain medium for amplifying light.

How does a fiber laser work?

A fiber laser works by pumping a high-intensity beam of light into a doped fiber, which amplifies the light through stimulated emission.

What are the advantages of fiber lasers?

Fiber lasers have several advantages over other types of lasers, including high efficiency, high beam quality, compact size, and low maintenance requirements.

What are some common applications of fiber lasers?

Fiber lasers are used in a wide range of applications, including industrial cutting and welding, medical procedures, telecommunications, and scientific research.

What is the difference between a fiber laser and a CO2 laser?

Fiber lasers use optical fibers as the gain medium, while CO2 lasers use a gas mixture. Fiber lasers are typically more efficient and have higher beam quality than CO2 lasers.

What is the lifespan of a fiber laser?

The lifespan of a fiber laser depends on several factors, including the quality of the components and the operating conditions. With proper maintenance, a fiber laser can last for many years.

What is the cost of a fiber laser?

The cost of a fiber laser varies depending on the power output and other features. Entry-level fiber lasers can cost several thousand dollars, while high-end models can cost hundreds of thousands of dollars.